Producing wine and distilled liquors from natural ingredients is frequently associated with the formation of undesirable contaminants. This may affect the colour, odour and taste of the product, in addition to potentially reducing their shelf-life.

Therefore, many finishing processes incorporate a purification or decolourisation step involving the use of specialised activated carbons.

These will be designed to remove any unwanted light or dark colours, herbaceous tastes and odour compounds, such as from fumes or smoke. Such compounds may have been generated in the process or during the growth, harvest or storage of the plant or fruit. This includes moulds or microorganisms which can develop on the grape during poor weather conditions.

Activated carbon has been an indispensable auxiliary in wine making for many years as it is a highly effective decolourising and purifying media.

Depending on the specific product to be purified, the production process being used, and the operating conditions, different types of activated carbon may be chosen.

Purification with Activated Carbons

Chemviron provides a range of carefully selected products to satisfy the demanding requirements of this particular industry, in either powder or granular forms. Purification with powder-activated carbons is typically carried out in batch operations, where a defined quantity of the powder carbon is dosed into the purification vessel.

Chemviron produce a premium range of primarily powder-based activated carbons in Europe, from renewable marine pine wood feedstock, under the Acticarbone® and ENO Anticromos® trademarks. This specialised production process is highly controlled to generate high-performance carbons with excellent physico-chemical properties.

These high purity, low-ash Acticarbone® carbons are especially suited for colour removal and adsorption of unwanted taste and odour compounds. They are also designed with a controlled pH, compatible with the application and a very high permeability, which improves productivity during filtration. This means that are a cost-efficient solution for removing unwanted contaminants from wine and distilled liquors.

All the Acticarbone® range are vegetable carbon-based and comply with the Food Chemical Codex (FCC).

Granular activated carbons are typically applied for purification processes by passing the solution through a granular carbon bed. For acidic or higher purity applications, specific grades of activated carbon with low acid-soluble ash would be required.

For detailed advice on the most appropriate carbon for your application, please contact our technical support team.

Wine Purification

Wines and fortified wines, such as vermouth, contain a complex range of natural colour bodies originating from the grapes, which affect the visual appearance. Other molecules such as from certain yeasts or moulds can also add undesired tastes and off flavours.

The plant pigments are organic compounds belonging to the groups of carotenoids, chlorophylls, anthocyanins, and betalains. Generally, these colour components can effectively be reduced or removed by suitably selected chemically activated powdered carbons.

Darker colours from polyphenolic compounds such as tannins, anthocyanins, melanoidin, flavonoids, and oxidation products of polyphenols can be effectively adsorbed with minimal dosage rates. Lighter colours or colour precursors such as phenolic oxidation products and catechins can also be effectively removed.

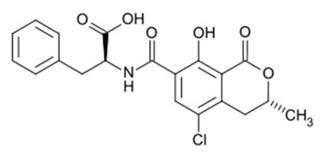

Wines may also contain toxins produced by fungi growing on the grapes. An important example is Ochratoxin A (OTA) – shown below. This has carcinogenic and possibly neurotoxicological properties and is one of the most abundant food-contaminating mycotoxins in the world. OTA can be removed efficiently with activated carbon.

Activated carbon is also used to correct the organoleptic characteristics of musts, fermenting musts or white wine due to grapes being affected by fungus. The removal of undesirable colour, odour and off-taste require a selective process that does not impair the desired or typical characteristics of the product, such as the ‘bouquet’ of the wine.

In oenological applications, the use of activated carbon is highly regulated and is described in the International Oenological Codex, published by the International Organisation of Vine and Wine (OIV).

This Codex describes the allowed raw materials and methods of manufacture, the physical forms of the oenological carbons and their applications within the industry. It also details the quality requirements and related test methods for activated carbon products. Only a pure activated carbon of vegetable origin can be used.

The Acticarbone® and highly activated ENO Anticromos® are the most efficient solutions for decolourisation and organoleptic correction of the musts and require a minimum dosage to enhance the colour, taste and odour.

In addition to the OIV Codex, there is also European legislation relating to the purity level of foodstuffs. This includes Regulation 149/2008/EEC which establishes the Maximum Residue Levels (MRLs) of pesticides.

Distilled Liquors or Spirits

When distilling spirits, such as rum, whisky, brandy, sakes, soju and vodka, removing unwanted colour, taste, and odour are of a primary concern, particularly as they also affect their ageing stability. However, these are made up of a long list of compounds which are different for every application. Testing is often required to select the most appropriate activated carbon to be used.

The first distillate from the still can contain undesirable elements such as methanol which is toxic and cannot be removed by activated carbon. The first part of the collected alcohol is called ‘’Heads’’.

This contains more alcohol-soluble compounds, such as acetaldehyde, which has a green apple odour, acetone, and acetates. It often has a fruity/ester character, some of which are desirable and can be used in blending. The main distillate collected is called ‘’Hearts’’ and is the part that tastes the best and is of the best quality.

The last portion of alcohol that is produced is the ‘’Tails’. This contains heavier alcohols, bitter fusel alcohols or oils, and other unwanted by-products such as acetic acid or furfural which has an almond smell, which are more water-soluble.

Activated carbons may also be used for chill haze prevention, ageing stability, colour and taste removal where appropriate to achieve the required smoothness and purity.

Specific activated carbons are used for these applications to remove light and dark colours, taste, odour and a range of undesirable contaminants. For more advice on how we can help you – please contact us.

So How Can Chemviron Help You?

If you have a wine or spirit that you would like to be purified or you just want to improve your process, please provide us with some basic process details. Our experienced technical team can then make an assessment and advice on the most appropriate carbon and way to proceed for your application.

The main design considerations for powder activated carbon use are the dose rate, contact time and the dosing point in the process. For the treatment of wine, these rates will greatly depend on the nature of the wine to be treated and on the required result.

If this is a new application and granular carbon is being considered, why not use mobile carbon filters, available on a rental basis. These include stainless-steel vessels that can be easily operated inside production plants.

Once the purification step is complete or the carbon is spent, the mobile carbon filter may be exchanged for a new unit. In these applications, the spent carbon would be normally suitable for recycling by reactivation for reuse.

If you need help on the choice of activated carbon, the potential for reactivation, the help of our mobile carbon filter service or just some further advice, please contact us – contact our technical team.