How mobile activated carbon filters removed taste and odour from drinking water for a European water utility company.

Emergency Response to Algae Contamination in Drinking Water: A Taste and Odour Crisis Solved

Responding to new water quality issues quickly, effectively, and sustainably has become a significant challenge for many water utilities. When a seasonal taste and odour issue caused concerns in the local community, a European drinking water utility required a rapid and capable solution.

This case study highlights how Chemviron’s activated carbon technology provides a rapid and effective solution to purify drinking water. We delivered and installed 14 CYCLESORB® MA20 mobile carbon filters, prefilled with FILTRASORB® 400 activated carbon. The customer urgently needed to address the drinking water quality for the local community, and we were able to deliver our solutions rapidly.

Project Scope: Algae Contamination of Lake Water and Organic Contaminants in Drinking Water Supply

Freshwater lakes provide a valuable source of drinking water. However, in recent years, due to a warmer climate, the level of organic matter that is present in all sources of freshwater has increased. This organic matter typically comes from the decay or breakdown of vegetation, animal life, bacteria, and algae that then enter our freshwater sources from lakes, streams, or rivers.

Most natural organic matter is usually removed during the coagulation, flocculation, and filtration stages of the water treatment process before chlorination. However, during the long summer months, when seasonal algae widely form, the metabolites they form when they decompose, releases, extremely high loads of organics into the water. This can significantly affect the efficiency of treatment plant operations and so the quality of the resulting drinking water.

With increasingly fluctuating temperatures as a result of climate effects, this is becoming an ever more frequent occurrence over recent years.

This particular waterworks site has seen an increase in such seasonal taste and odour issues, which have been an unpleasant addition to the local tap water. It came to the point where the resulting operational challenges and public health concerns meant a prompt and effective solution was required to remove the excessive organic matter and quickly restore the drinking water quality.

Activated carbon is widely used as an additional means to capture any dissolved organic matter that may escape processing during the coagulation stage, but the challenge then became to find a fast and effective solution with the lowest possible capital expenditure cost.

For water treatment solutions, fixed granular carbon beds are typically constructed in concrete, where the activated carbon is hydraulically conveyed into and out of the filters from bulk tankers. However, when time is of the essence, this would not be possible.

The Challenge

Fast, Cost-Effective Taste and Odour Removal from Drinking Water

Chemviron met with the customer to assess how we could help them find a solution, and the use of mobile carbon filters was proposed. Mobile carbon filters are essentially movable carbon vessels that can be transported to and from a customer’s site. They are already prefilled with the selected activated carbon. Once on site, these mobile carbon filters are designed for quick offloading and easy interconnection into the water treatment system. Our Plug & Purify concept means that the mobile carbon filters are immediately ready for start-up and use, minimizing operational downtime.

The selection of the appropriate activated carbon to be installed in these mobile carbon filters then becomes an important question, as not all activated carbons are the same

Granular activated carbon is a universally recognised solution for the removal of a wide range of organic contaminants from drinking water, since its first application over 50 years ago. When activated carbon was originally installed in water treatment works, it was in fact primarily for taste and odour removal.

As each water source is different, the Chemviron team can use its extensive worldwide technical experience as well as a bank of performance data to help provide the most appropriate technical solution. Based on our assessment of the site, operating conditions, and treatment required, FILTRASORB®400 was recommended as the most suitable carbon for this site.

The Solutions

FILTRASORB® Activated Carbon Technology

FILTRASORB® is our range of re-agglomerated activated carbons that have been used worldwide for many years to remove taste and odour-forming compounds. These carbons are produced from selected grades of bituminous coal by a twin-stage process that agglomerates the product before steam activation. This agglomeration stage provides improved kinetics that can significantly increase the adsorption capacity over a single stage, compared to a direct activated product that may have similar specifications on paper.

The re-agglomeration process creates a pore structure within the FILTRASORB® carbons that is particularly effective for providing superior performance for the purification of drinking water and especially for the removal of trace impurities.

FILTRASORB® carbons are one of the most widely used granular carbons for drinking water treatment. This is primarily due to their:

CYCLESORB® Mobile Carbon Filters

Following a pre-visit to assess the site and review the access and proposed location, the customer was able to make the appropriate preparation for the arrival of our fleet of mobile carbon filters. Once the decision was made to proceed, speed was of the essence. Within three weeks, Chemviron delivered and installed fourteen CYCLESORB® MA20 mobile carbon filters, prefilled with FILTRASORB® 400 activated carbon.

Chemviron maintains a stock of mobile carbon filters which are available for such rapid deployment in a range of sizes to suit different processes and applications. CYCLESORB® mobile carbon filters are supplied on a rental basis and have become an effective and smart solution to enable fast and efficient water treatment.

The CYCLESORB® MA20 mobile carbon filters are specially designed for water treatment applications and are delivered to the site using a specially designed trailer from which they can be easily located in a convenient position. All they require on-site is a suitable flat and hard surface for installation.

The Chemviron team are trained in many aspects of activated carbon technology and can provide practical carbon support and advice on issues, new applications, or challenges.

For this project, Chemviron provided an on-site team to assist the client with the installation and set-up and to ensure the delivery was smooth and fluid. The on-site support provided by Chemviron was much appreciated by the client and the regional authority, who recognised the speed with which the project and works had been completed.

The installation of these 14 mobile carbon filters provides a security of supply for the drinking water quality and reduces the need for additional disinfection.

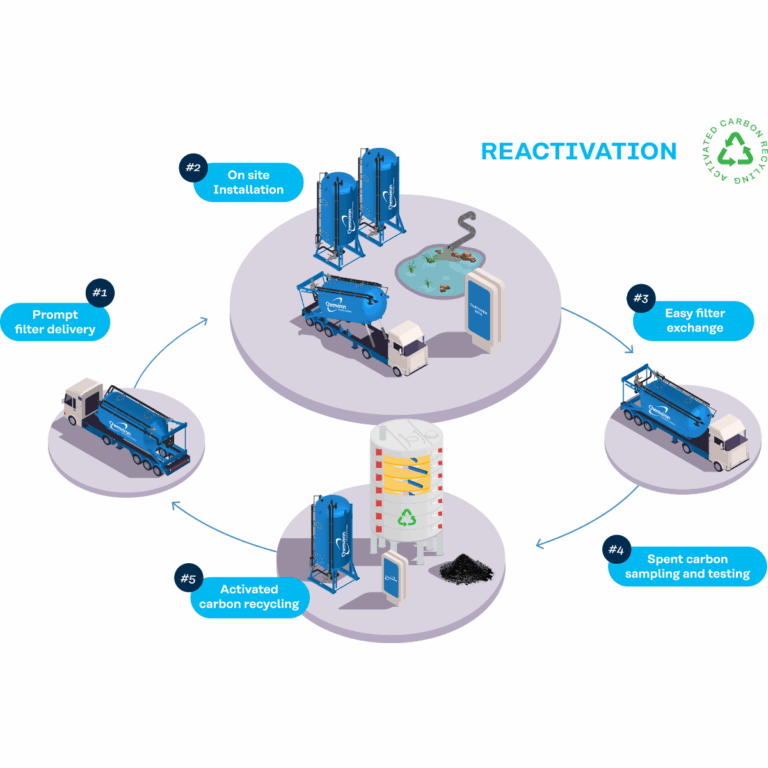

One of the significant advantages of using mobile carbon filters is their easy replacement. Once the mobile carbon filter is installed and when the activated carbon has been operated to the point where it is no longer considered effective, a replacement mobile carbon filter containing fresh or reactivated carbon will simply be delivered to the site. This can then be exchanged with the exhausted unit, so removing the need for any handling of the spent carbon by the user or on the user’s site. The spent or used CYCLESORB® filter may be collected at the same time minimising the ‘out of service’ or ‘offline’ period on site and saving transport costs in the process.

Alternatively, to further minimise process down time during a filter exchange, stand-by units may be located and connected next to the operating units. Then once a filter is exhausted, the operator can simply switch over to a fresh unit whilst the exhausted or spent vessel is exchanged.

The Results & Impacts

Improved Water Quality, Sustainability, and Community Confidence

One of the major benefits with activated carbon technology is that once the installed granular activated carbon becomes less effective in its use, it can be recycled by thermal reactivation. The reactivated carbon may then be returned to the original filter in the water works and put back into use. Reactivation involves treating the spent carbon in a high-temperature furnace where the undesirable organics on the carbon are thermally destroyed.

Recycling activated carbon by thermal reactivation is a sustainable and environmentally friendly technology that meets all our objectives to minimise waste and reduce CO2 emissions.

The combination of higher performing agglomerated carbons with the enhanced sustainability benefits through reactivation which provides an overall cost benefit to our customers.

Summary of the Solution

The rapid deployment and quick installation of 14 CYCLESORB® MA20 mobile carbon filters, prefilled with FILTRASORB® 400 activated carbon provided a low capital expenditure solution to restore safe and drinkable tap water for a local community in Europe.

Read more

Per- and polyfluoroalkyl substances (PFAS) are a large family of chemicals that contain carbon, fluorine and other elements. Historically, these may have been referred to under the term ‘PFC’ which stood for Per Fluorinated Chemicals. However, PFC is also used to mean ‘Per Fluorinated Carbons’ ie greenhouse gases and so this term is no longer used for PFAS compounds.

Disinfection By-Products and Natural Organic Matter Natural organic matter is …

Natural Organic Matter Natural Organic Matter (NOM), also known as …